Most people see vinyl flooring and picture the retro sheet flooring from grandma’s kitchen. That is not the case these days. Vinyl plank flooring now comes in gorgeous wood-look grain patterns and tile-like impressions and is more durable than ever.

During your online searches for the perfect vinyl flooring, you have likely come across the acronyms LVP, SPC, WPC, and LVT. At first glance, the differences may not be visible to the average consumer.

However, each has distinct composition characteristics that separate it from its counterparts. With so many options available on the market, how can you be sure you choose the best vinyl flooring composition for your space?

While the experts on our team have decades of flooring knowledge under their belts and can provide solutions while answering any questions you may have, knowing the differences beforehand can help speed up the shopping process.

In this article, we cover:

LVP vs. LVT

Luxury Vinyl Planks (LVP) cover every type of vinyl flooring designed to mimic wood while providing unique benefits. Luxury Vinyl Tile (LVT) describes vinyl products that mimic tile or stone.

When you call or visit flooring showrooms, you will find that LVP is a catch-all term. However, it is worth pointing out that not every vinyl plank is LVP.

Luxury Vinyl Plank Composition

LVPs are comprised of several layers, each working together to create a wood/stone look flooring that is resilient and low-maintenance.

The Three Layers of LVP Flooring

The Bottom Layer

Often referred to as the backer board, is a flexible base made of PVC (a synthetic plastic polymer) for stability.

The Central Layer

It makes the LVP water-resistant or somewhat waterproof (depending on brand and product) and provides strength for the flooring.

The layer on top of the central layer is the one that gives the LVP flooring its texture, pattern, and color.

The Top Layer

The layer at the very top is a clear protective coating called the wear layer; it makes the flooring scratch and stain-resistant.

LVP Flooring Wear Layer & Your Home

When shopping for LVP flooring, the wear layer thickness may be a factor in your selection process. Thinner wear layer planks are for residential flooring, and thicker wear layer planks are for commercial floors.

For residential flooring, vinyl plank floors under 12 mil in thickness are best. The most common vinyl plank thickness found in homes is 6 mil.

Vinyl Plank Flooring Installation

We often get asked by clients if a subfloor is necessary for LVP flooring installation. Unlike laminate flooring, most vinyl plank floor products can lay directly above the subfloor. However, since LVP flooring is glued down to the subfloor and permanently affixed via an adhesive, the subfloor condition must be good, free of damages, smooth, and dust-free.

Your specific LVP product will determine if you need to use a vinyl plank flooring underlayment. It is best to consult with a pro to discover if LVP or WPC, and SPC flooring are best for your space based on the condition of your subfloor.

Consult With a Flooring Expert and Get Free Vinyl Plank Flooring Samples to Take Home

WPC vs. SPC Vinyl Plank Flooring

Now that you know the different layers of LVP flooring, it is time to review WPC and SPC vinyl plank flooring, the pros and cons, and the available styles.

When visiting most flooring showrooms, you may not see WPC or SPC advertised above the various vinyl samples. You will likely see Ridgid Core Vinyl Plank.

Rigid Core Vinyl Plank can be either WPC (Wood-Plastic Composite, or Wood-Polymer Core) or SPC (Stone-Polymer Core). The first letter — “W” or “S” — refers to the composition of the core layer alone.

Like LVP, Rigid Core WPC/SPC flooring consists of layers.

The Three Layers of Rigid Core Flooring

The Bottom Layer

It consists of foam or cork. It provides a smooth, flat surface for the floor covering, adds foot comfort, and helps to reduce noise.

The Core Layer

Determines whether the Rigid Core flooring is WPC or SPC – made of a composite of wood or stone powder and plastic or resin.

The second to top layer is the vinyl layer. As with traditional vinyl plank flooring, this layer gives the flooring its texture, color, and pattern.

The Top Layer

Just as with LVP flooring, at the very top is a clear protective coating called the wear layer; it makes the flooring scratch and stain-resistant.

WPC and SPC Flooring Wear Layer Info

As with LVP flooring, WPC and SPC vinyl flooring are available in many plank thicknesses.

Since the core layer of WPC vinyl plank flooring consists of a wood composite and the core layer of SPC vinyl plank flooring consists of a stone composite, each thickness will vary. With SPC vinyl plank flooring, you will receive a thinner side profile of 3.2 to 7mm vs. a side profile of 5 to 8 mm with WPC vinyl plank flooring.

Rigid Core Luxury Vinyl Plank Flooring Installation

Unlike LVP flooring installation, which gets glued down to the subfloor, WPC and SPC vinyl plank flooring is float-installed. There is no glue used. Instead, an interlock system uses tongue-and-groove ends to connect each plank. Rather than be glued to the subfloor beneath it, Rigid Core luxury vinyl planks float above the subfloor beneath it.

Consult With a Flooring Expert and Get Free Vinyl Plank Flooring Samples to Take Home

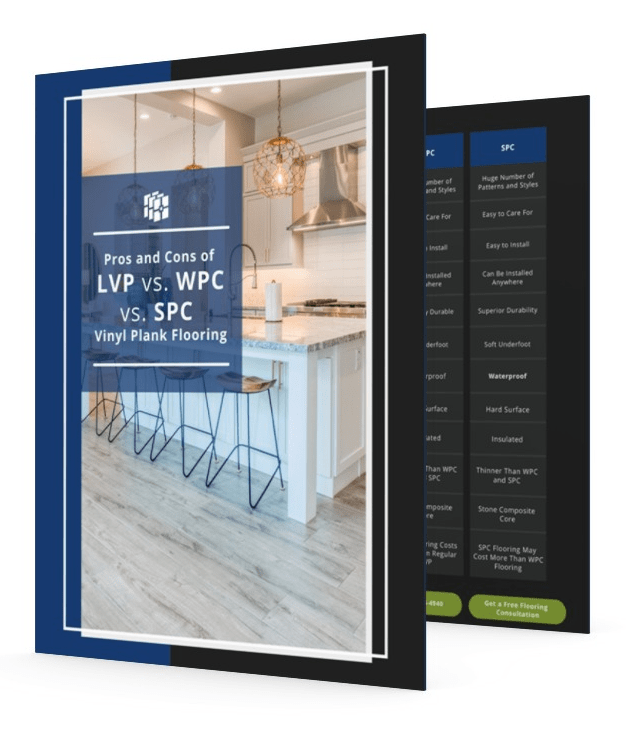

Pros and Cons of LVP vs. WPC and SPC Vinyl Plank Flooring

Download our guide and discover the pros, cons, and differences of LVP, WPC, and SPC vinyl flooring in a side-by-side comparison chart.

LVP, WPC, and SPC Flooring Styles

Whether searching for mixed-width planks and tiles, wood-Look LVP, light and dark colors, or something truly unique, our showroom features hundreds of flooring options. Shop before you visit by walking our virtual showroom.

Particular Vinyl Plank Flooring Brands

Are you looking for something particular?

As an authorized dealer of Mohawk, Shaw, Provenza, and more, we carry LVP, WPC, and SPC vinyl plank flooring in various shades, grain patterns, and textures. Visit your favorite retailer websites to check out the products that await you in our showroom.